Process Equipment Maintenance Series (Part I)

In the process of biopharmaceutical process, the liquid distribution tank, liquid storage tank, ultrafiltration/chromatography/reactor process tank, etc., are basically equipped with weighing system. A weighing system usually includes 3 to 4 load cells (Loadcells), junction box (Junction box), transmitter (Transmitter),HMI/PLC (option).

If the weighing system error exceeds the limit or is abnormal during use and verification, it needs to be verified or calibrated to make it meet the process requirements. When the emergency cannot wait for the equipment supplier or weighing system supplier to come to service, the production personnel and engineering personnel can carry out verification and calibration operations first.This article briefly describes the operation process of weighing verification and calibration from the transmitter end.

calibration process usually consists of three stages: verification-calibration-re-verification

verification

a. Confirmation before daily use

can choose a fixed value of the weight, such as 20kg ~ 50kg weight, respectively, placed in the position near each support foot for testing, to confirm whether the reading is within the error range, and the balance between each weighing module. Assuming that one of the three weighing modules is damaged, only placing the test weight in the center of the tank or adding water cannot find the problem, while placing the weight test near the tank support leg one by one can find the failure of a single weighing sensor in time. For some large jars that are not easy to place weights, a small platform can be designed on the leg of the jar for placing weights.

B. Verification during verification or measurement

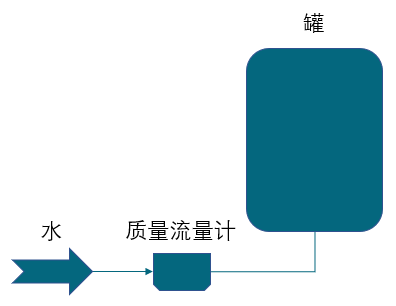

verification or measurement is usually more rigorous, and three or more points are selected: 0-20%,40-60%,80-100% (the high point is as close to the full scale as possible). For large tanks, hundreds to thousands of kg of weights cannot be placed. The cumulative volume function of the mass flowmeter can be used for testing. It should be noted that the pipeline and flowmeter should be filled with PW or WFI water at a slow speed at the initial stage to remove excess air. At this time, the water source should be closed, and the flowmeter and weighing system should be cleared to complete the preparatory work. During the verification of each point, it is also necessary to prevent the pipeline air intake from affecting the volume accumulation accuracy of the flowmeter. The following schematic diagram shows that the mass flowmeter can be placed under the tank to achieve better exhaust. During the water injection process, the water pressure should be constant and the flow rate should be stable. A manual diaphragm valve can be added between the mass flowmeter and the water source and the opening can be adjusted to limit the flow.

decide whether to calibrate or not: calibration is not required if the verification result is within the acceptable range, and calibration is required if it is beyond the acceptable range.

provides an example of how to perform the calibration operation.

teachers, if there are any details in this article, please contact RealTop Technical Service Hotline 0513-82104020 or send an email to service@realtopbio.com for our technical support.

cooperation

welcome teachers in need to inquire!

RealTop Biology can provide a disposable mixing system with a volume of 10L-3000L, and can be equipped with online detection functions such as weighing, jacket, temperature, pH, conductivity, pressure, etc,welcome teachers in need to inquire!